TRIANGULAR TEABAG MACHINE

TPB-200DS

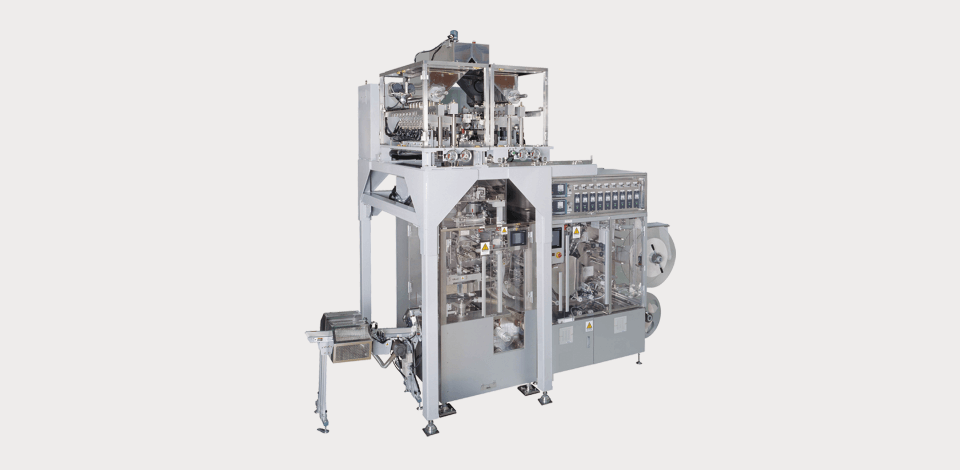

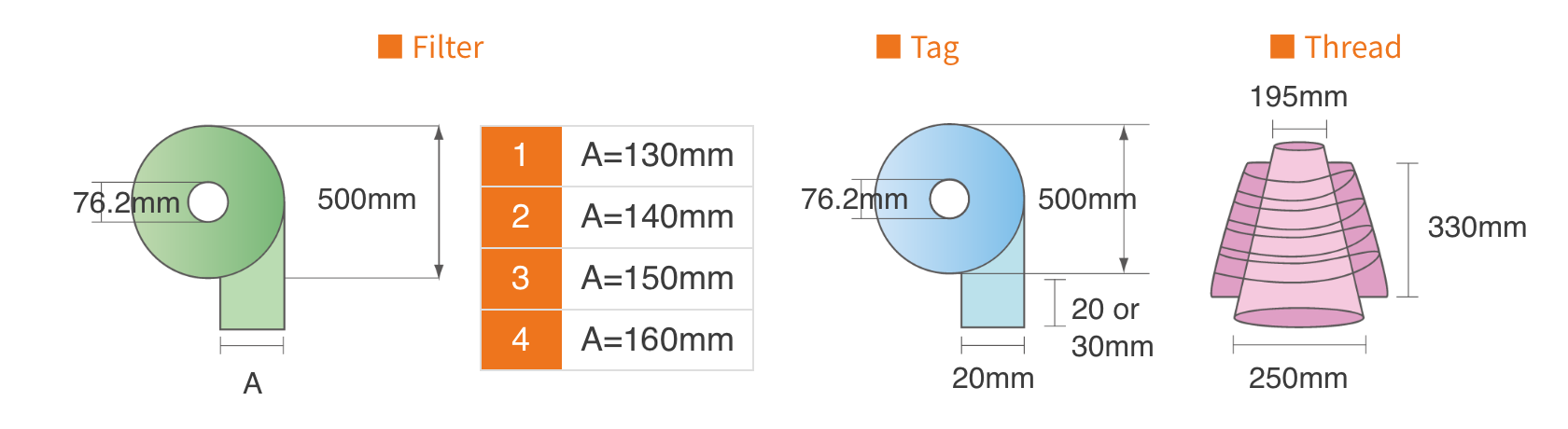

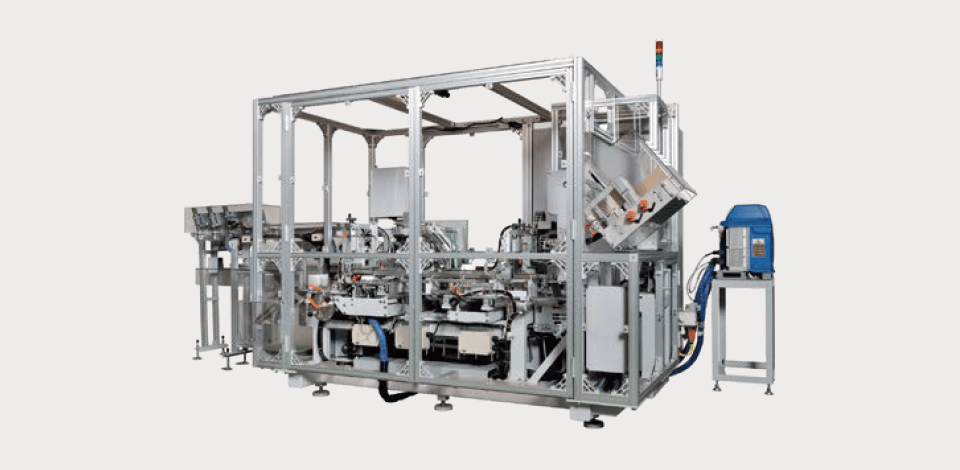

TWINKLE is the most advanced high speed tea bag manufacturing machine on the market.

Advantages of TPB-200DS

HIGH SPEED

TPB-200DS makes triangular as well as flat type tea bags at a speed of 200 bags per minute. It is possible to make 25 million bags per year if operated 8 hours per day for 260 days.

PRODUCTIVITY

Once the rolls of filter,thread and tag paper have been fitted, the TPB-200DS will keep running for many hours without stoppage for material replacement. The TPB-200DS is equipped with many sensors which detect defects such as the joints on the filter and tag, and automatically ejects the faulty bags by air blow, thus minimizing down time.

COST SAVING

On TPB-200DS, expensive tagged material is not necessary. You are able to run inexpensive regular roll nylon(polyester) mesh or nonwoven, tag paper and thread. The saving in material cost is substantial.

WIDE VARIETY

With the electric weigher mounted on the equipment, TPB-200DS packs many different kinds of tea such as herbal tea, leaf tea and fruit tea with high weight accuracy.

Product video

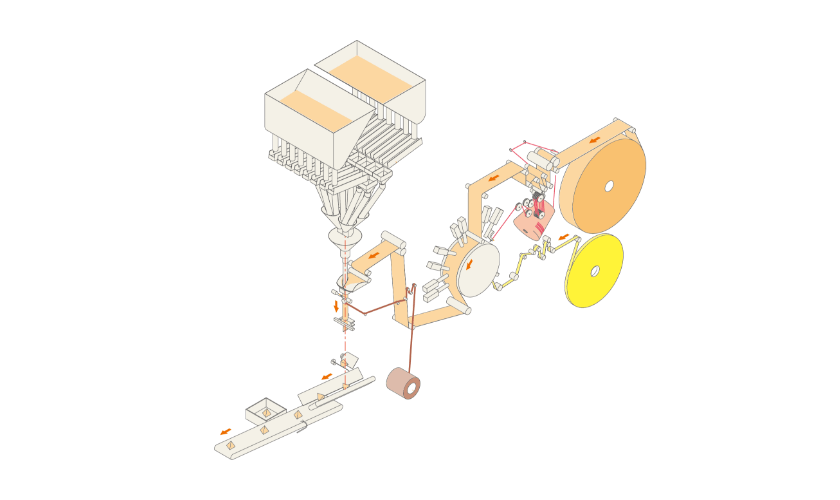

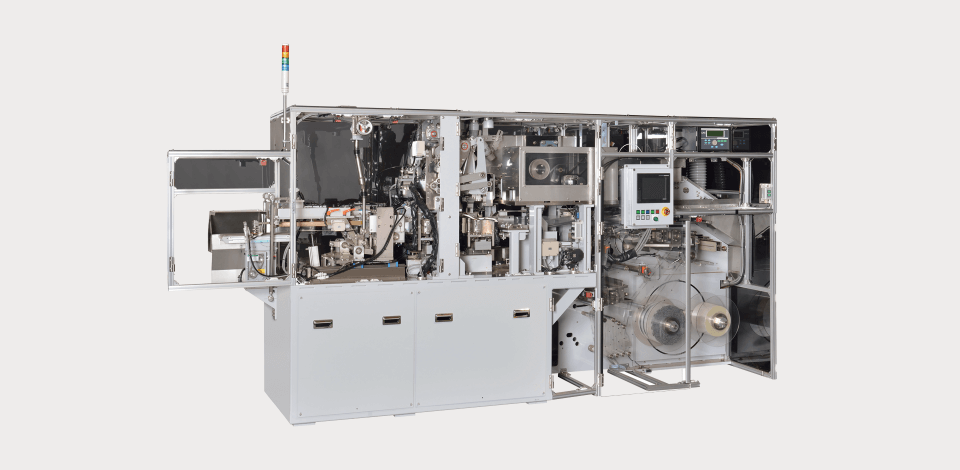

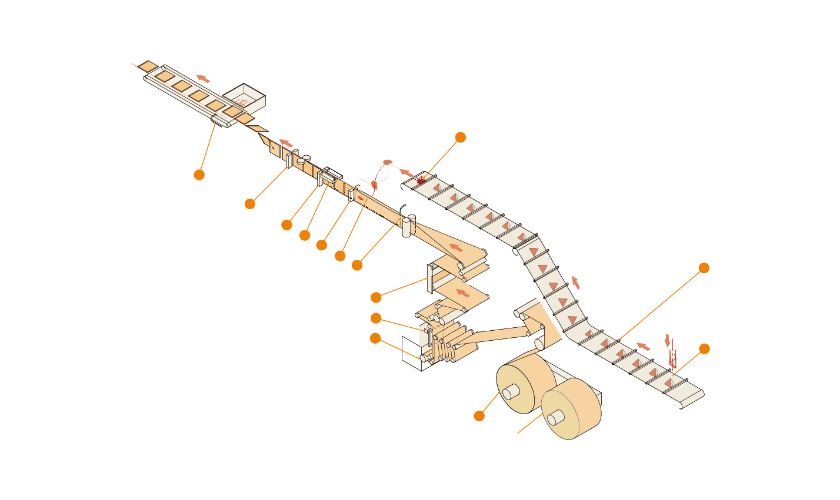

SPECIFICATIONS / PROCESS

TPB-200DS

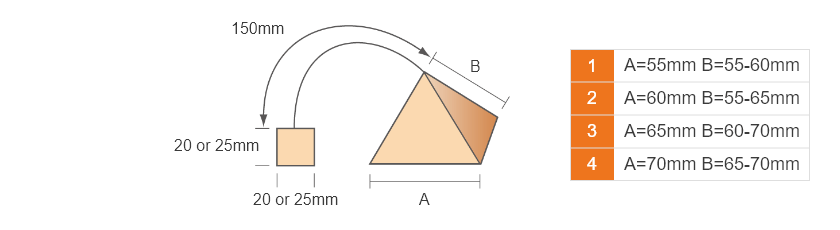

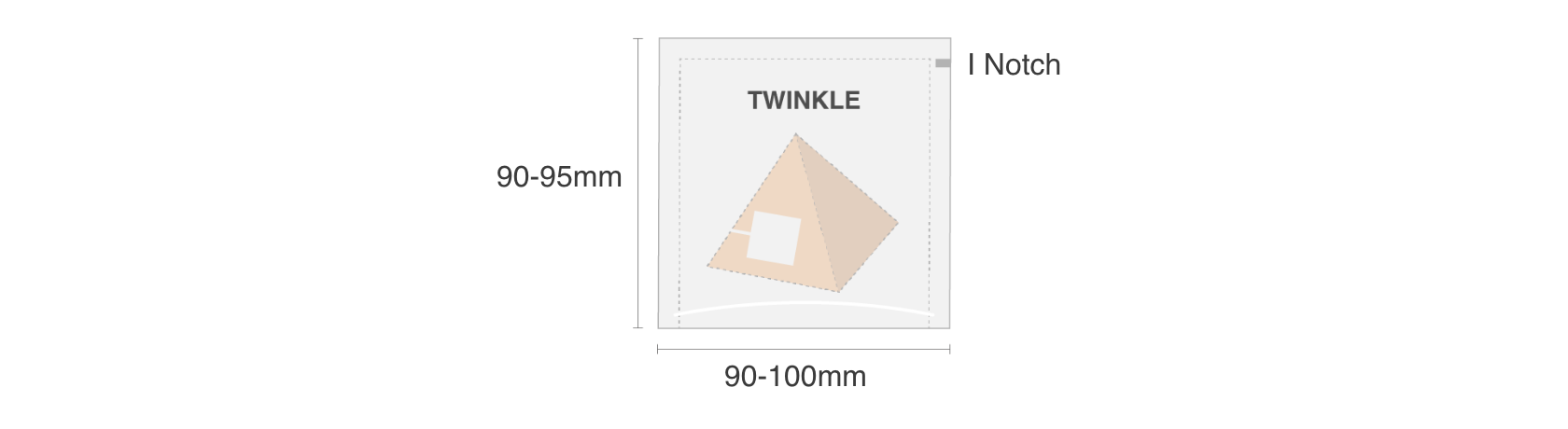

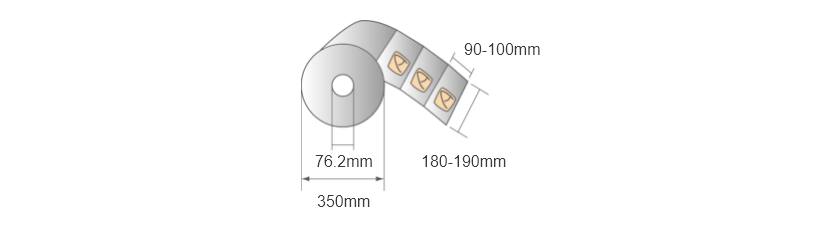

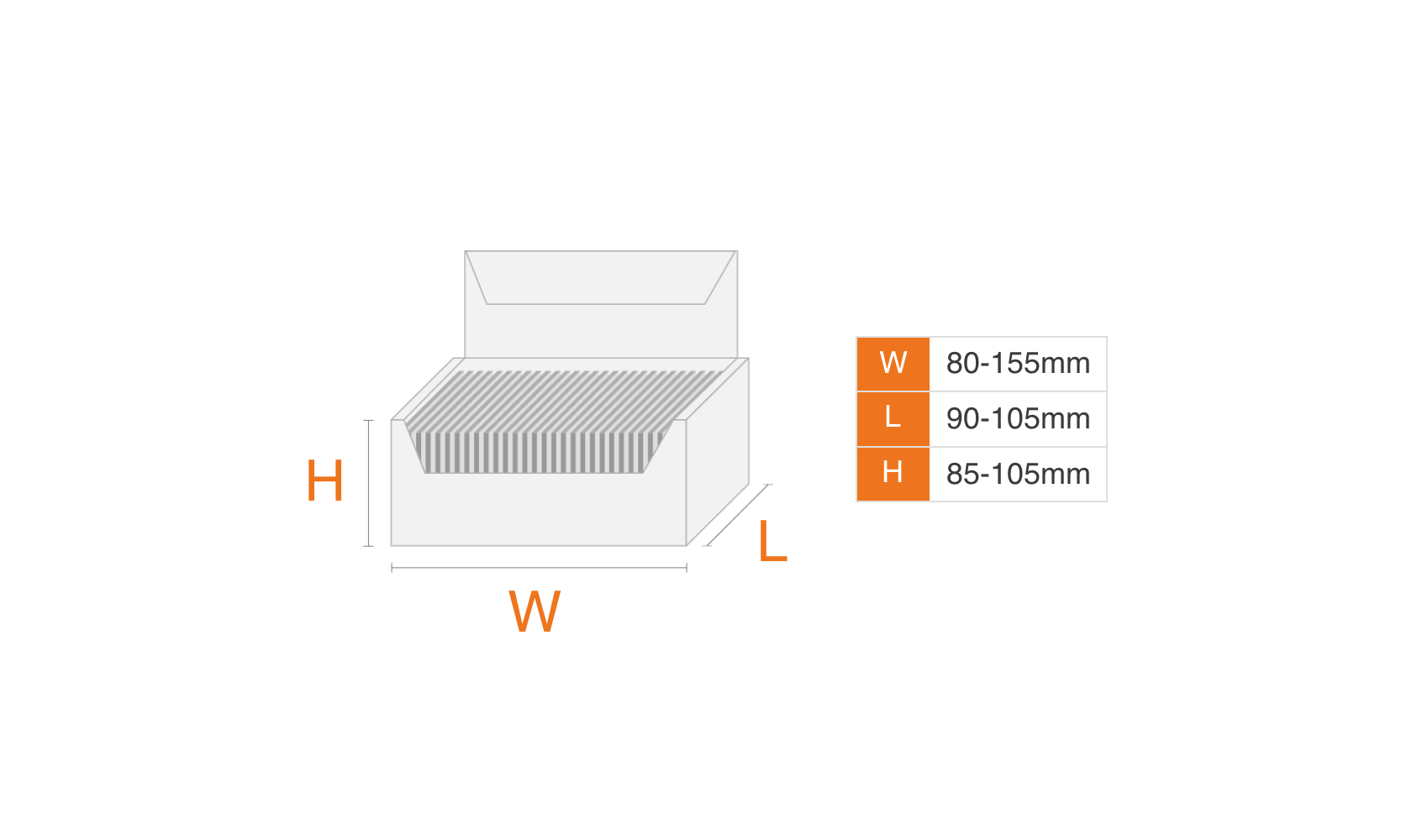

TEABAG SIZE

MATERIAL

PICK UP WHAT FINISHED PRODUCT

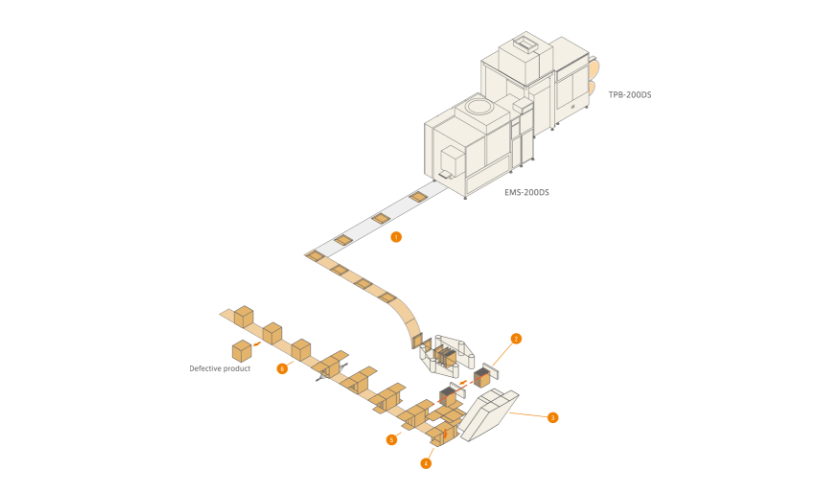

ENVELOPER EMS-200DS

ENVELOPER EMS-200DS

EMS-200DS the enveloper can be connected and synchronized with TPB-200DS. Packing a teabag into the envelope makes the products more attractive for consumers. Infusion of nitrogen gas into the envelope, which keeps the tea inside fresh, is possible as optional.

SPECIFICATIONS / PROCESS

EMS-200DS

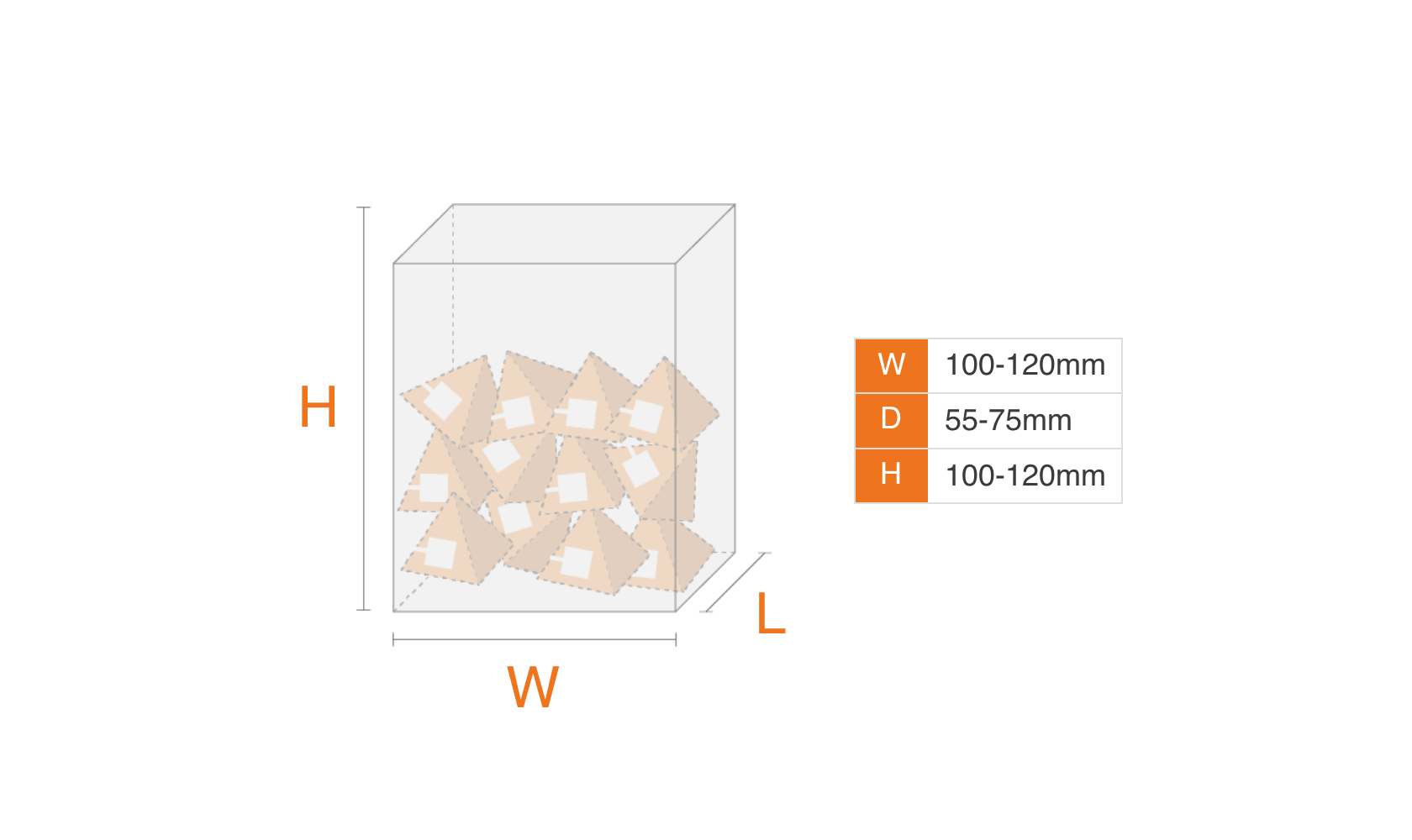

ENVELOPE SIZE

ENVELOPE FILM

Envelope Cartner ACT-25

NEW Envelope Cartner ACT-25

ACT-25 accumulates enveloped teabag feed into a carton. Compare with other machines, accumulation unit is made smaller and reduce installation area.

SPECIFICATIONS / PROCESS

Envelope Cartner ACT-25

CARTON SIZE

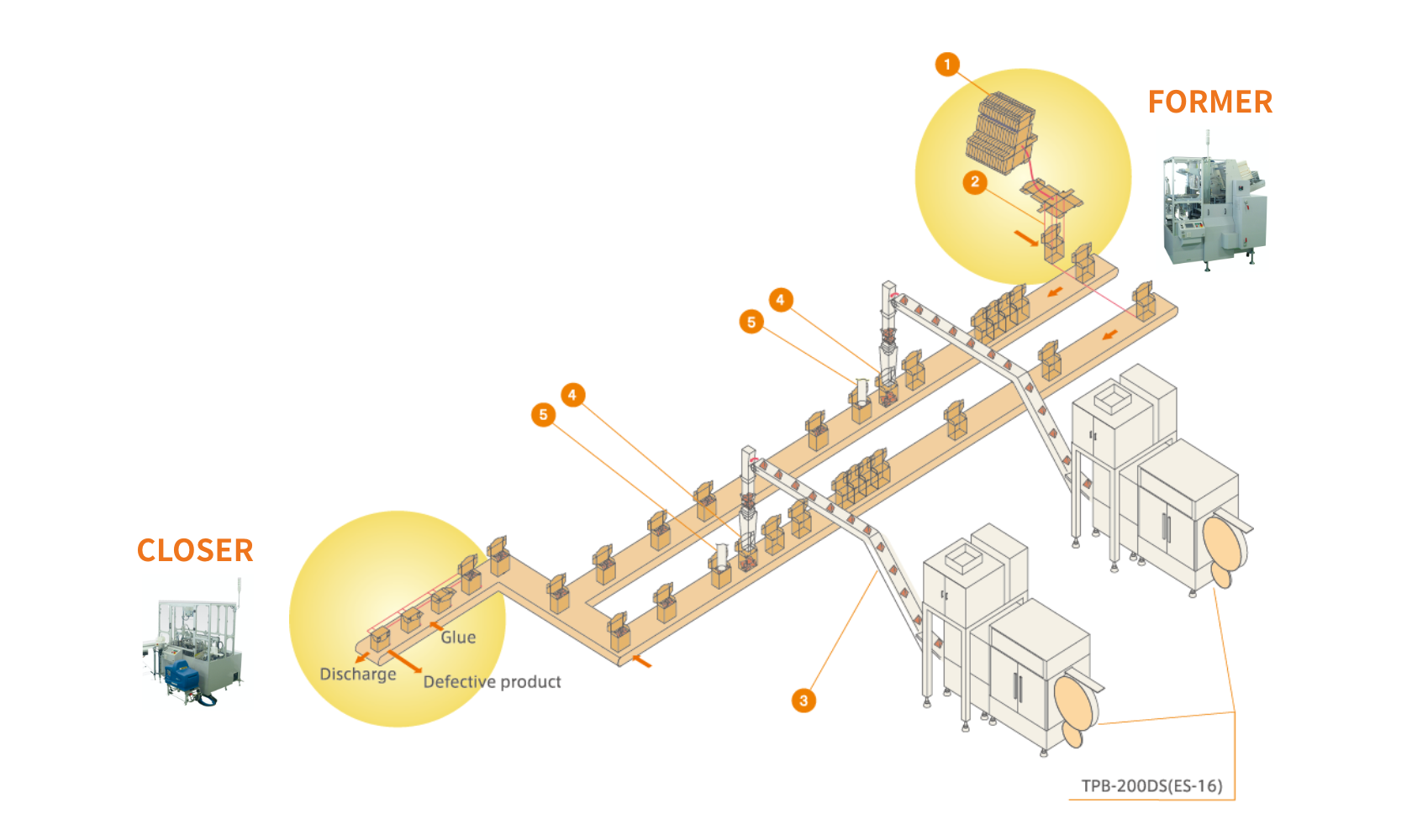

CARTONING LINE FOR TEABAG

CARTONING LINE FOR TEABAG

20 CARTON PER MINUTE These are just standard specifications. TSUBAKIMOTO can provide specific specifications according to your requirements.

SPECIFICATIONS / PROCESS

CARTONING LINE FOR TEABAG

CARTON SIZE

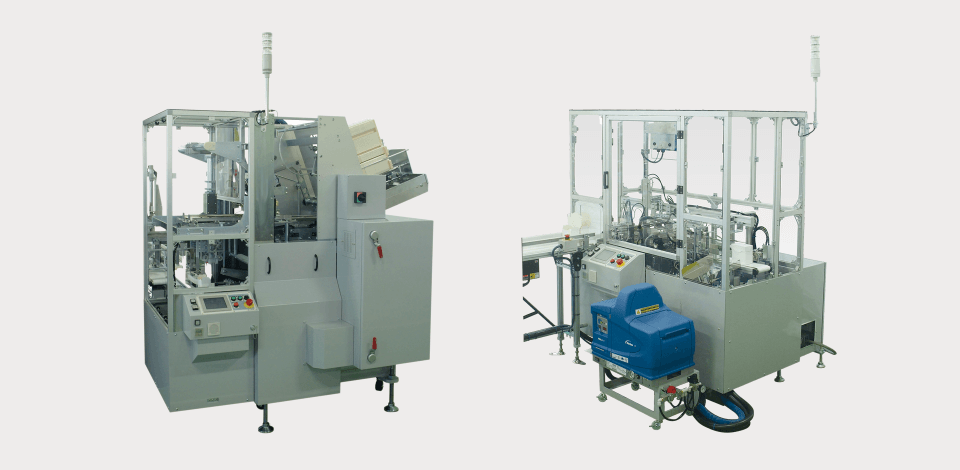

FORMER

Blank cartons are fed on the slant magazine by hand, then they are fetched up by vacuum cap one by one, and positioned on to the female mould. Male mold pushes the blank carton down into the female mould, and carton forming is completed.

CLOSER

①Product-filled-carton with short side leading.

②Re-close small flap and hood cover are bent.

③Hot melt applying.

④Side flap and front panel are bent and closed.

ACCUMULATION UNIT

ACCUMULATION UNIT

The tea bags are counted and grouped into a batched predetermined amount, such as 10, 20 and 25 bags. After accumulation,in the two stage timing hoppers, the tea bags can be fed to a carton positioned underneath the timing hoppers.

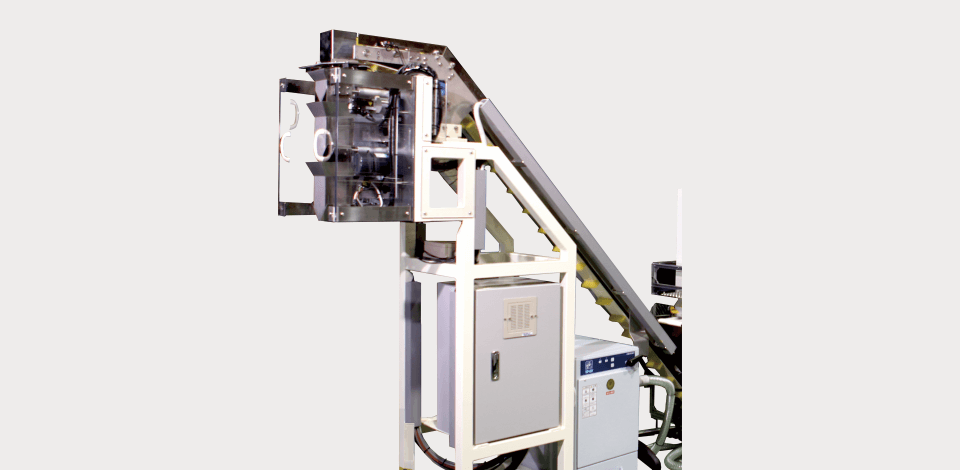

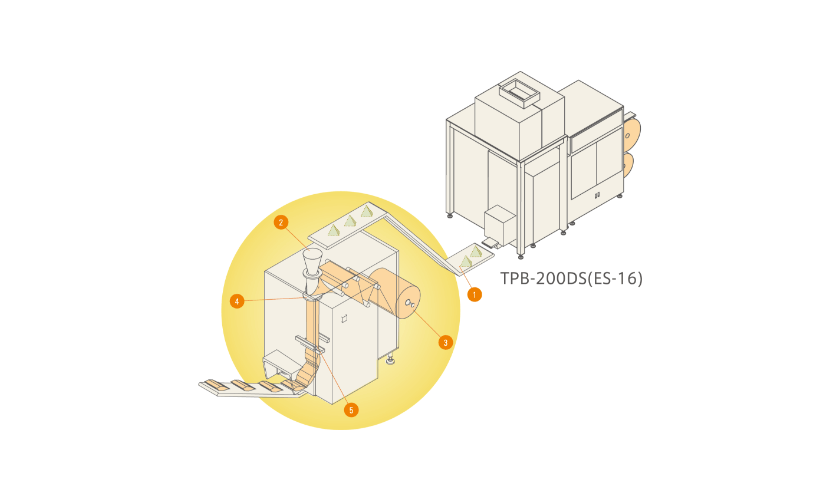

VFFS Packing Machine

VFFS Packing Machine

This machine packs every 10-50 tea bags into a pouch or gusset bag, using film roll.

SPECIFICATIONS / PROCESS

VFFS Packing Machine

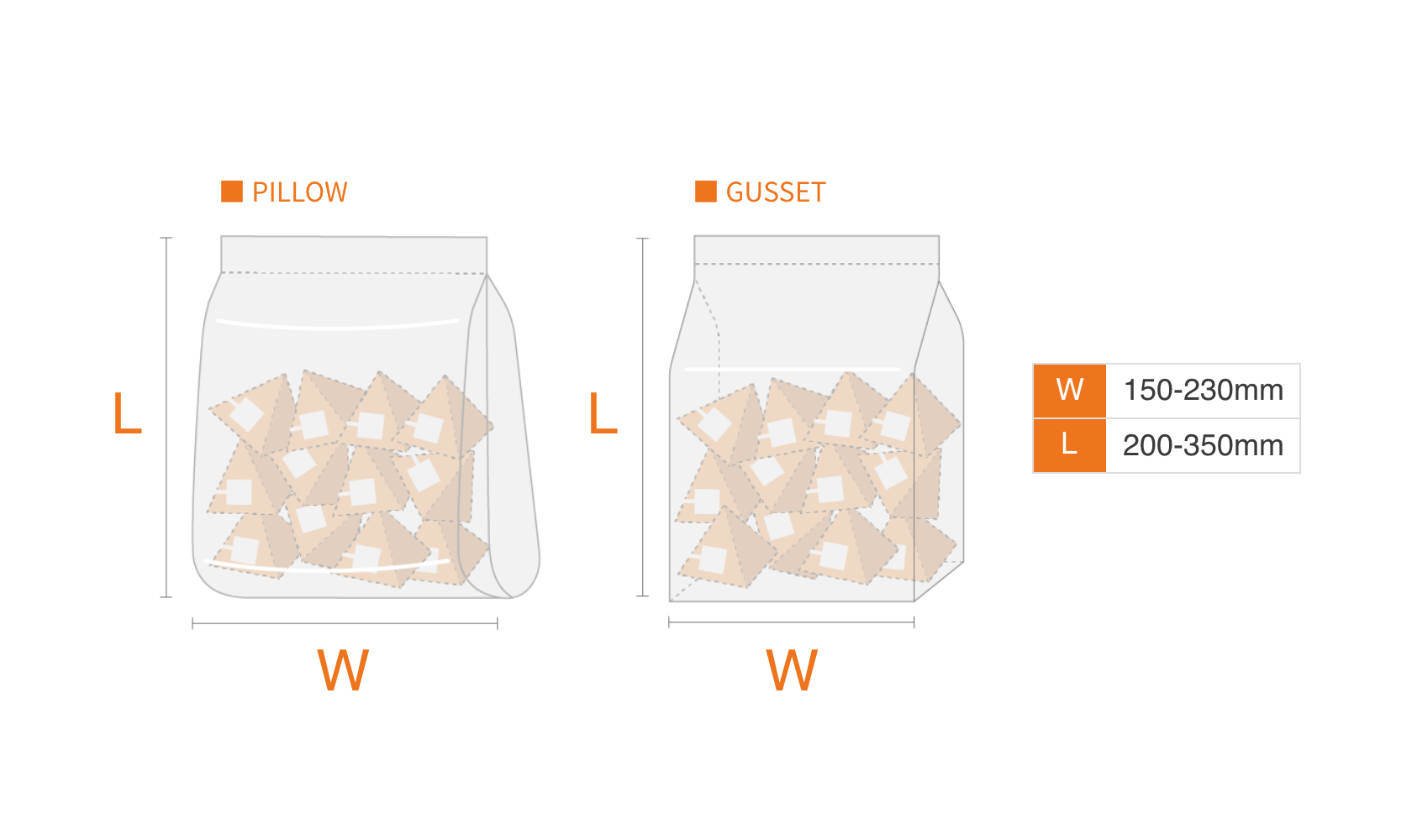

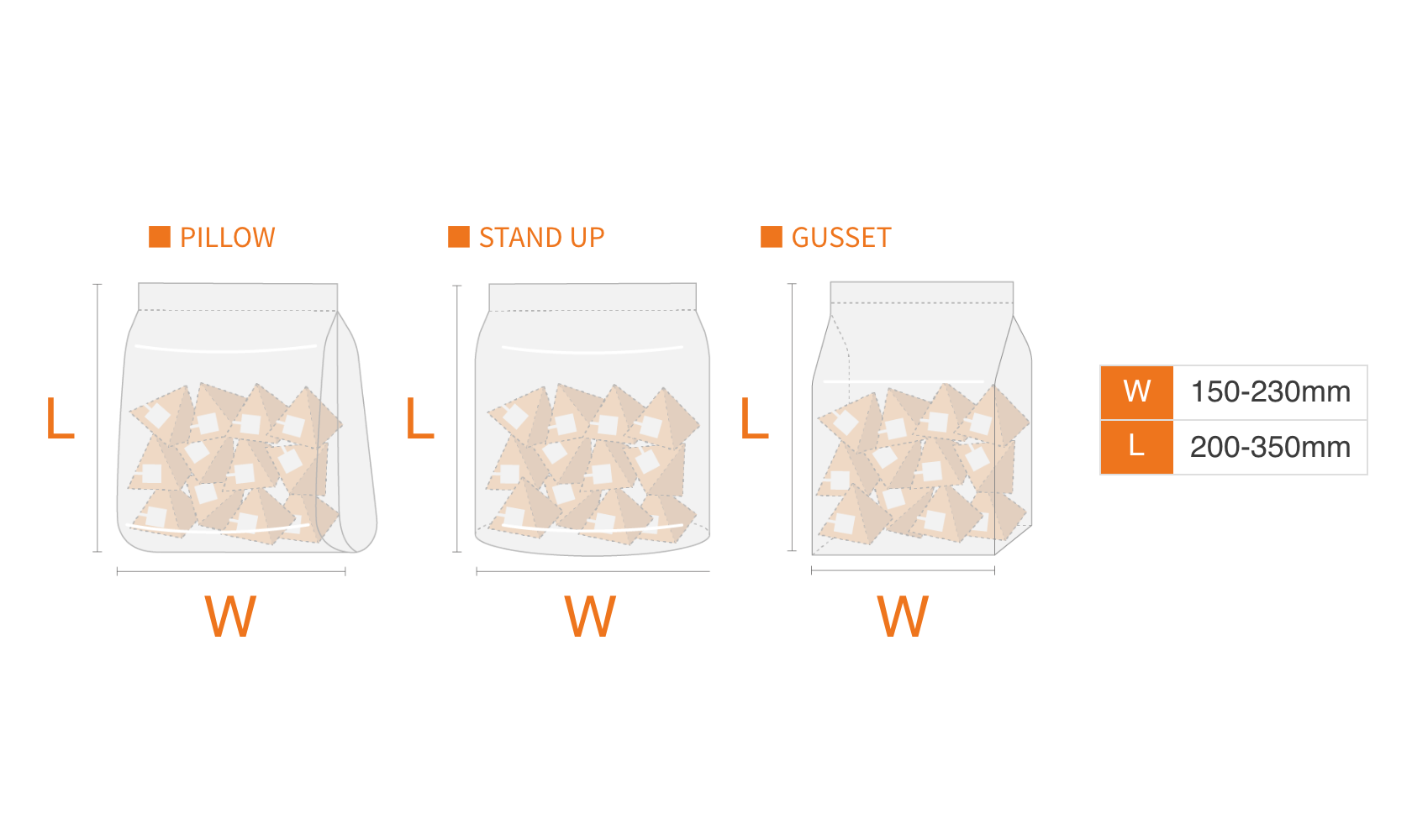

BAG TYPE

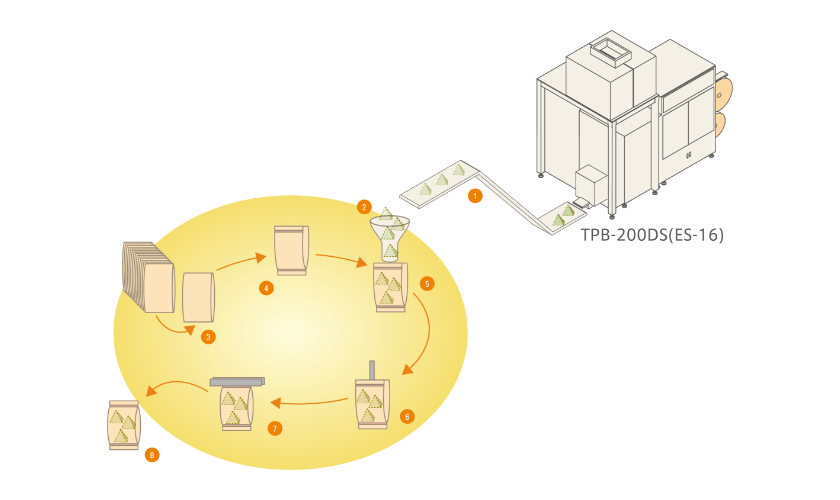

POUCH FILL / SEALING MACHINE

POUCH FILL / SEALING MACHINE

This machine packs every 10-50 tea bags into a pouch or gusset bag, using pre-formed pouches. Blank pouches are fed on the slant magazine by hand, ①Open a bag. ②Feed teabags. ③Infuse Nitrogen. ④Seal and close a bag.

SPECIFICATIONS / PROCESS

POUCH FILL / SEALING MACHINE

BAG TYPE

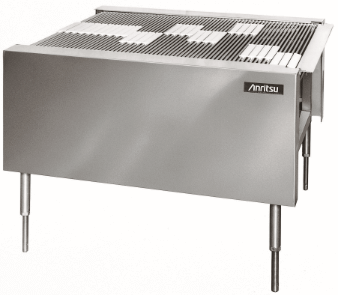

CHECK WEIGHER

with high accuracy to separate the products with the

correct weight from under weight and over weight.

The products with deviated weight will be ejected by an air blower.

Furthermore, individual data and statistic data can be

saved to a USB memory stick by installing the USB Memory Unit.

CHANNELIZER

VACUUM CONVEYORS

dummy,dummy,dummy,dummy,dummy,

dummy,dummy,dummy,

dummy,dummy,dummy,dummy,dummy,dummy,

dummy,dummy,dummy,

dummy,dummy,dummy,dummy,dummy,dummy,

dummy,dummy,dummy,

dummy,dummy,dummy,dummy,dummy,dummy,

dummy,dummy,dummy,

dummy,dummy,dummy,dummy,dummy,dummy,

dummy,dummy,dummy,

dummy,dummy,dummy,dummy,dummy,dummy,

FAQ

ADVANTAGES OF TRIANGULAR TEABAG?

A triangular teabag is for superior infusion.

It allows for more space, then this ensures a faster infusion and much better flavor and taste.

It is possible to pack such as herbal teas and fruit teas into this type of teabag.

Also, the shape itself is an attractive feature.

Tsubakimoto have not only the biodegradable filter material but also the compostable packaging film "TF-BIO" developed for helping the recent environmental issue. The film is heat sealable film for low and high speed machine, and it makes a product keep freshness.

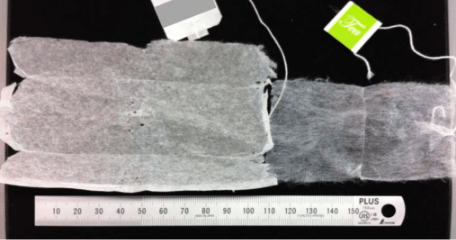

MATERIAL USAGE?

Compare with traditional double chamber type teabag, triangular teabag is able to reduce about 60% filter consumption.

HOW LONG DOES IT TAKE FOR CHANGE OVER?

About 10 minutes.

HOW LONG DOES IT TAKE FOR CLEANING WHILE CHANGE OVER?

It depends on tea material, but it usually takes 15 - 20 minutes.

Biodegradable / PLA material can be used on TPB-200DS?

Yes. You will be able to use not only filter, but tag and thread.