ABOUT SUSTAINABLE PACKAGE

TSUBAKIMOTO KOGYO has expanded the product line of sustainable package to help reduce the effects of recent environmental issues such as marine plastic polution and plastic waste disposal. We have various materials and products related to and dealing with "COMPOSTABLE", "BIOMASS" and "PLASTIC REDUCTION".

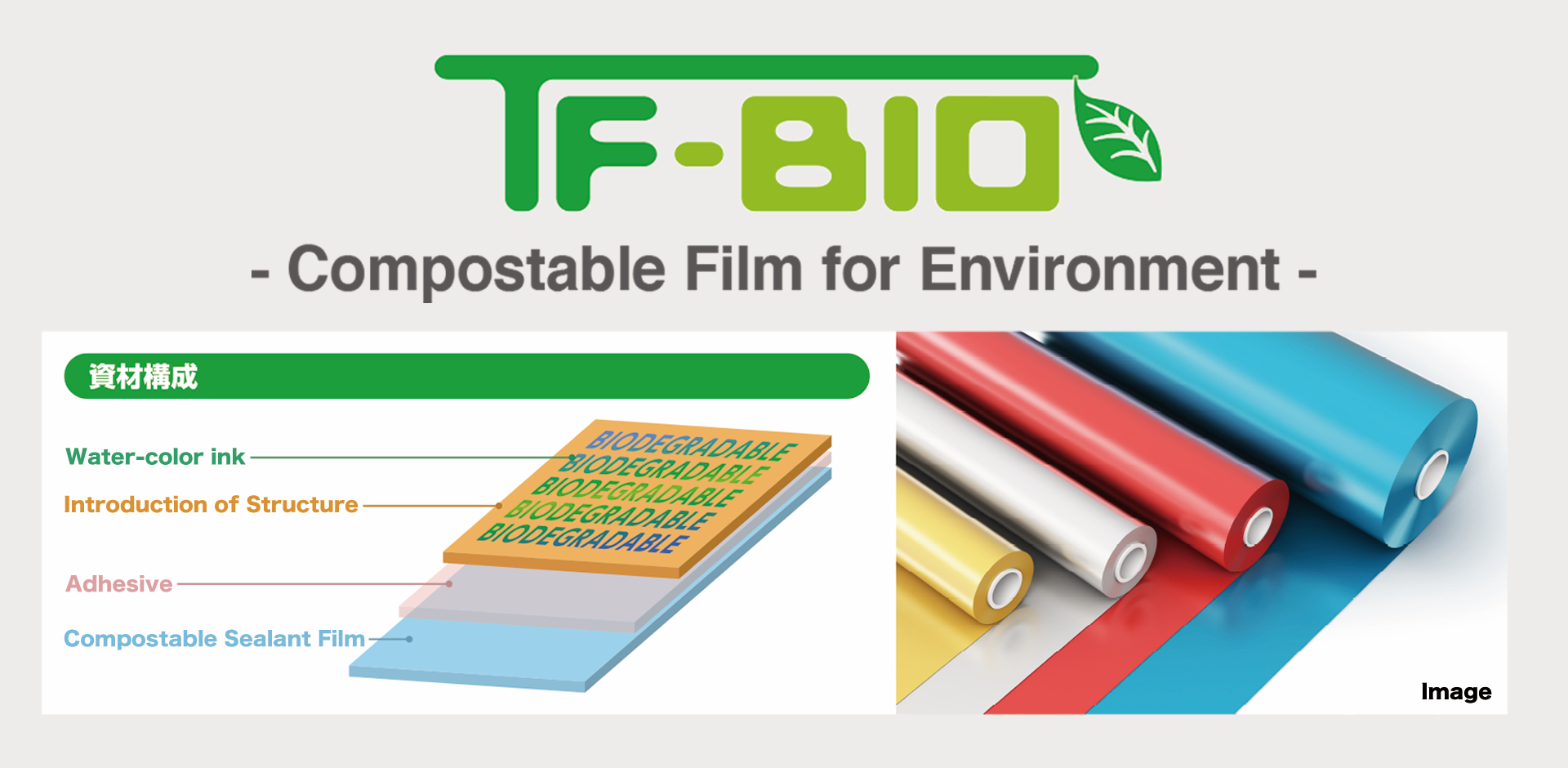

COMPOSTABLE PACKAGING FILM

"BIO-BASED AND COMPOSTABLE"

“TF-BIO” is a package film composed of compostable films. Due to the multi-layer structure, it

has excellent sealing properties and can be used for high-speed machines. Water vapor barrier

and oxygen barrier film are also available in our product line.

In addition to food hygiene certification, we can propose products according to such needs as

biomass mark and compostable certification mark. Our teabag manufacturing machine “TWINKLE” and

drip coffee manufacturing machine “PROSSIMO” are also able to operate with these films.

❶ Eco friendly packaging film with

compostability

❷ Multi-layer structure with excellent

heat sealing and barrier properties.

❸ It can be proposed with specifications

that meet your needs such as film rolls and bag-making products.

BARRIER PAPER WITH COMPOSTABLE LAMINATION

"PLASTIC REDUCTION" "PAPER"

It is a paper based package with barrier properties. it meets “Plasetic reduction” requirements.

❶ Paper mark can be added.

❷ Improved biomass rate and compostability

rate

❸ Compostable laminate layer

PAPER-BASED MATERIAL

"PLASTIC REDUCTION" "PAPER"

It is a paper based molded material. It meets “Plastic reduction” requirements.

❶ Paper mark can be added.

❷ Improved biomass rate and compostability

rate

❸ Injection molding and Sheet molding are

possible.

Example : Food tray, Cutlery, Bottle, Rice tray, gift tray

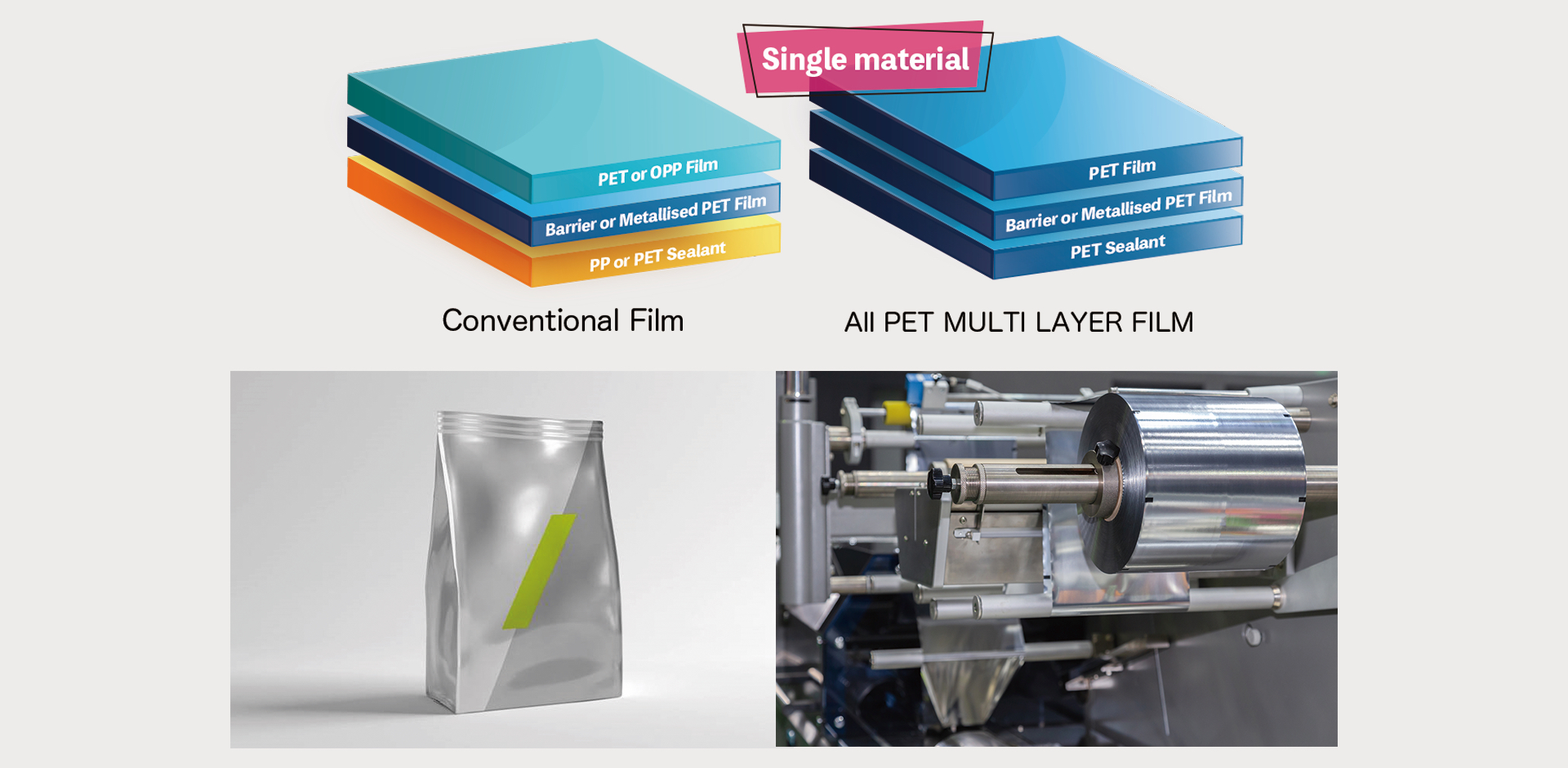

ALL POLYESTER MULTI LAYER FILM

"RECYCLE" "MONO-MATERIAL"

It is a multi-layer package film made of a single material. Monomaterials (made of a single material) make recycling suitable.

❶ Monomaterials(made of a single

material) make recycling suitable.

❷ Existing manufacturing methods can be

used.

❸ Heat resistance, aroma retention and low

adsorption are improved by using all polyester.

Example : Disposal bag (Smell barrier), Teabag pouch (Smell barrier), Food bag (Microwave-safe)

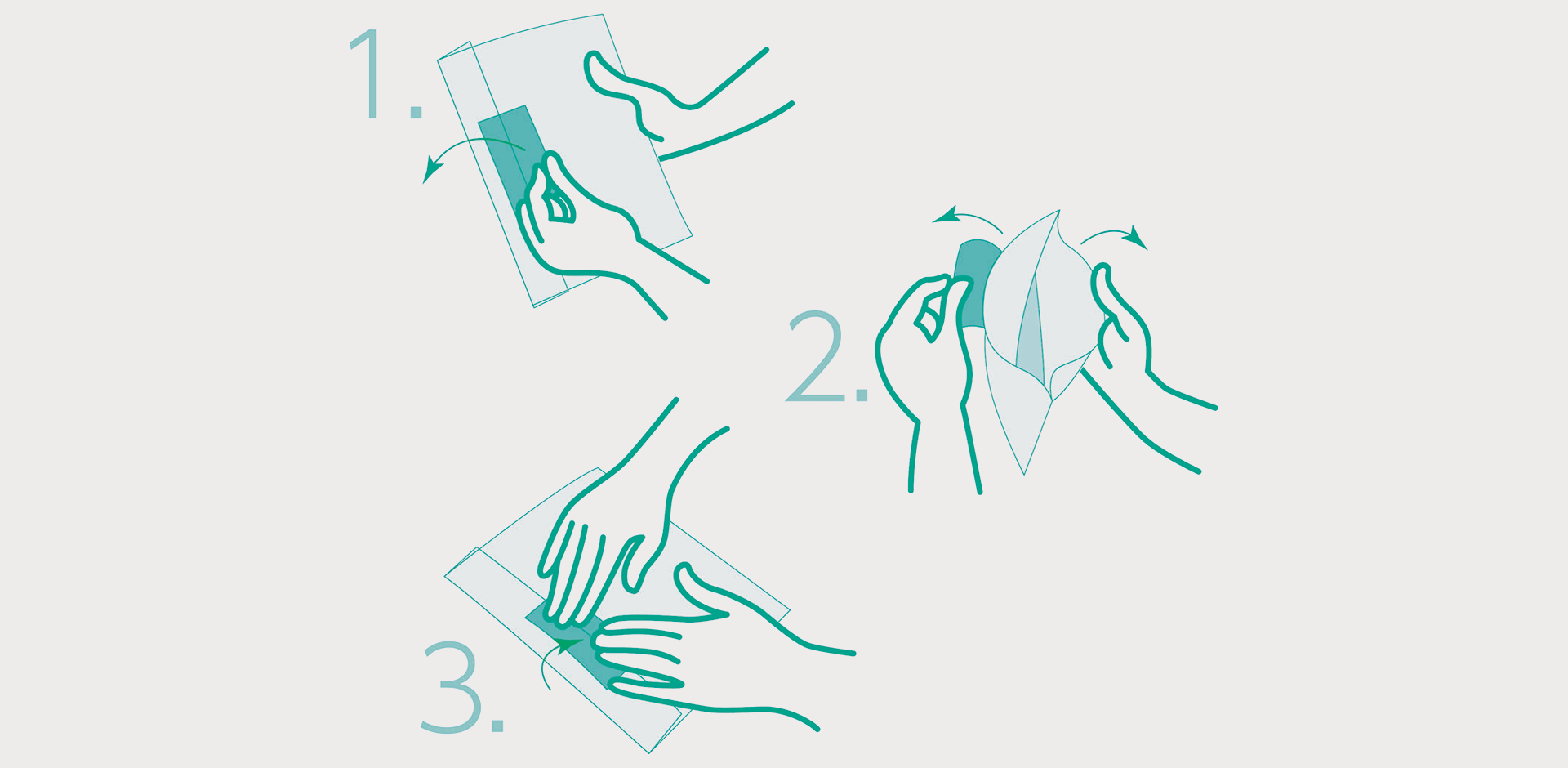

RECLOSEABLE PACKAGE

"PLASTIC REDUCTION"

A new package that replaces the deep-draw products used in traditional ham and cheese products.

It is expanding in Europe because of reducing the amount of plastic used and energy saved on the manufacturing line.

❶ Easy open, reclose function

❷ The reclose function prevents

dehydration and drying of foods in the refrigerator even after opening.

❸ Up to 50% reduction in plastic usage compare to deep-draw products.

Example : sliced ham, sliced cheese, rice crackers, dry foods, etc

PLA Woven, PLA Non-woven

"BIOMASS" "COMPOSTABLE"

Woven and Non-woven, made from PLA material which is made from plants and is compostable

❶ 100% PLA Product

❷ Biomass and compostability approved

❸ Expanding in Europe for environmental protection.

Example : Beverage filters, Agricultural materials, masks

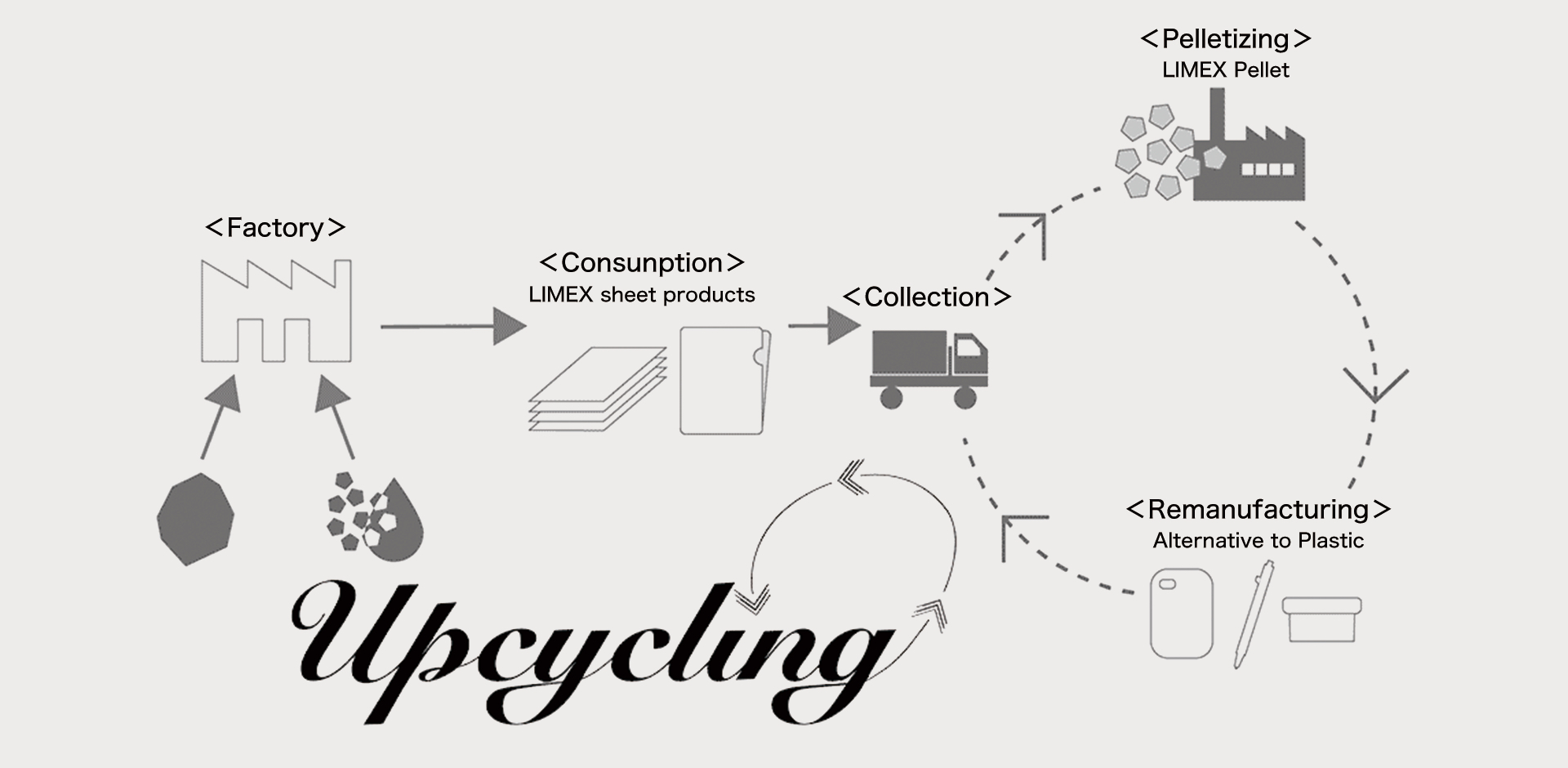

New material "LIMEX" ~Alternative to Paper and Plastics~

"PLASTIC REDUCTION"

It is a molded mateial mainly made of limestone which is abundant on a global scale

❶ Made of limestone which is abundant on a global scale

❷ Almost no need for water and wood in production (compared to paper)Reduced use of petroleum (Compared to plastic)

❸ Existing manufacturing methods can be used.

※Upcycling Sustainable “manufacturing” with the goal of creating products with higher value than the original products.

Application

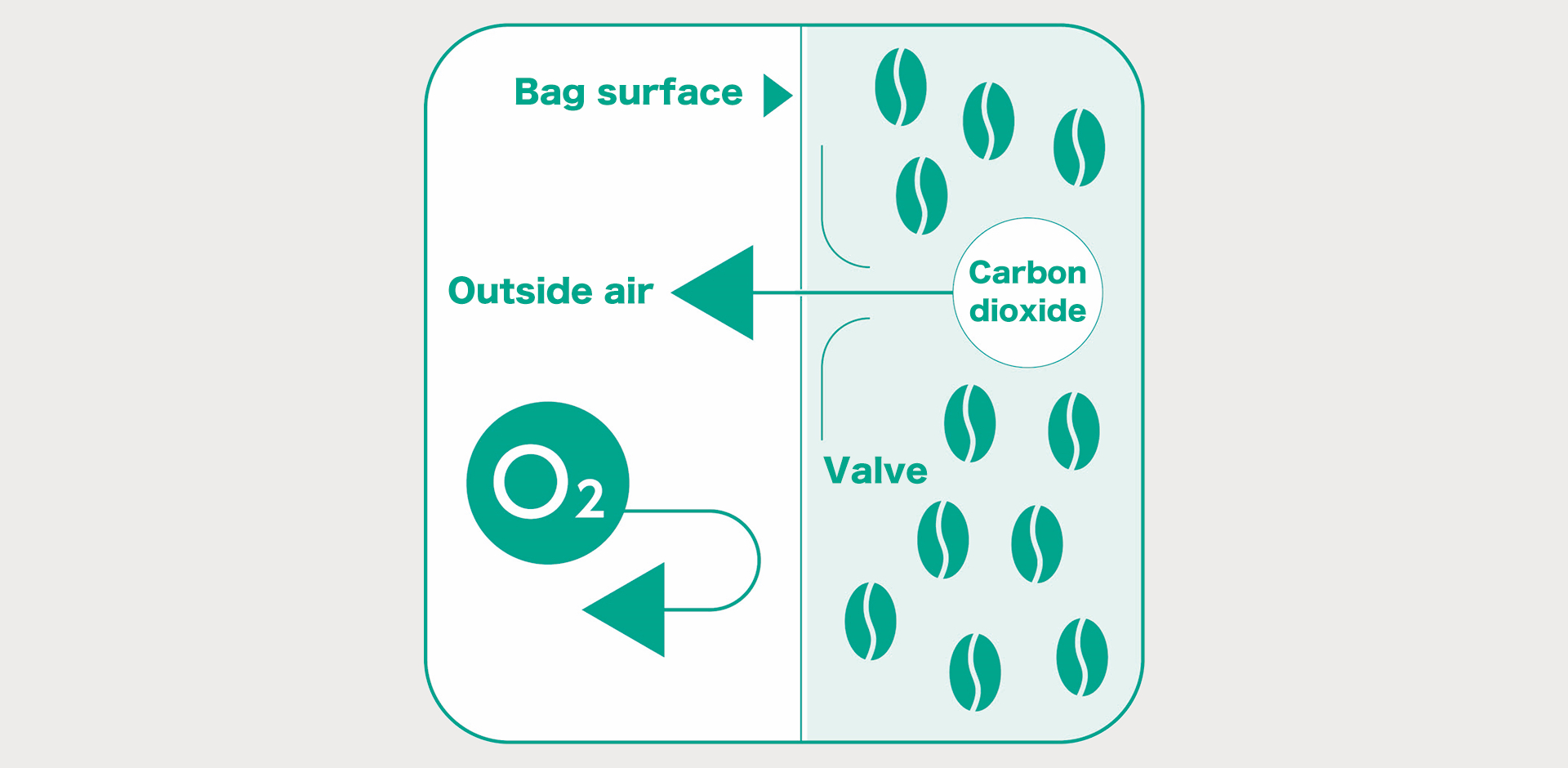

Degassing valve

"Space-saving" "PLASTIC REDUCATION"

One way Air Valve made of non-woven fabric. Made-in-Japan product that has accumulated many years experience.

❶ Space can be saved bacause the valbe has no irregularities.

❷ Reduced resin usage compared to conventional resin valve.

❸ Increased speed of filling machine is possible when you use valved film.

Example : Coffee products

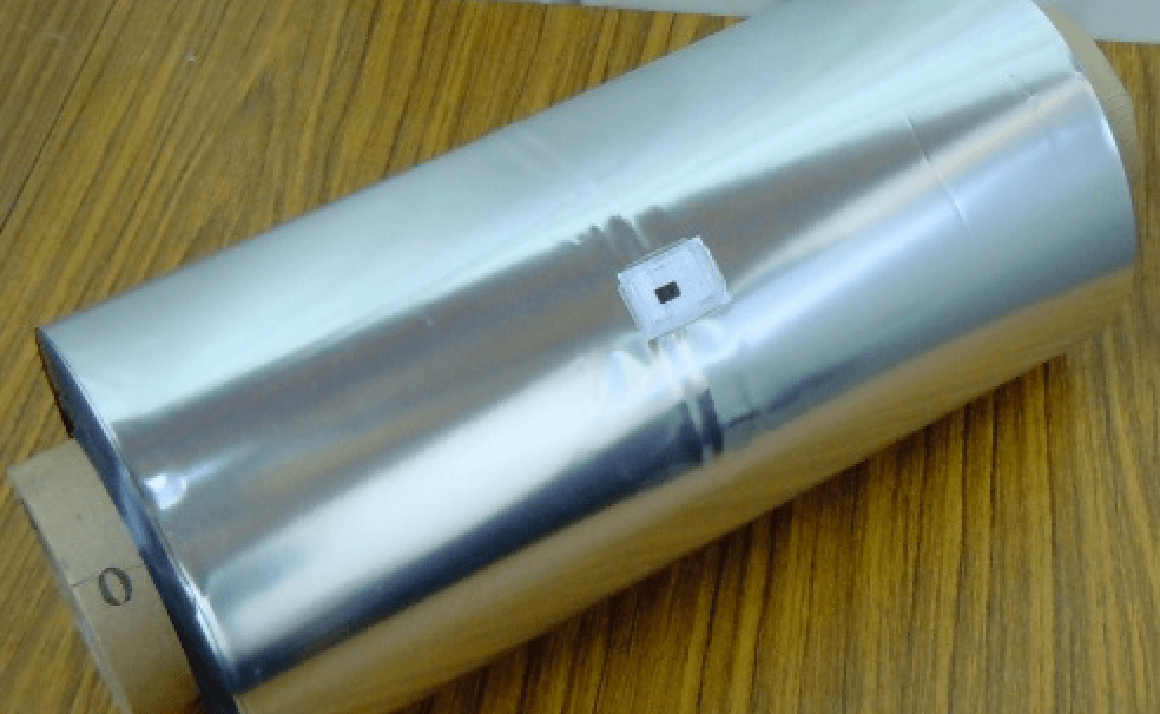

Valved Product

Valved Roll